mankhwala

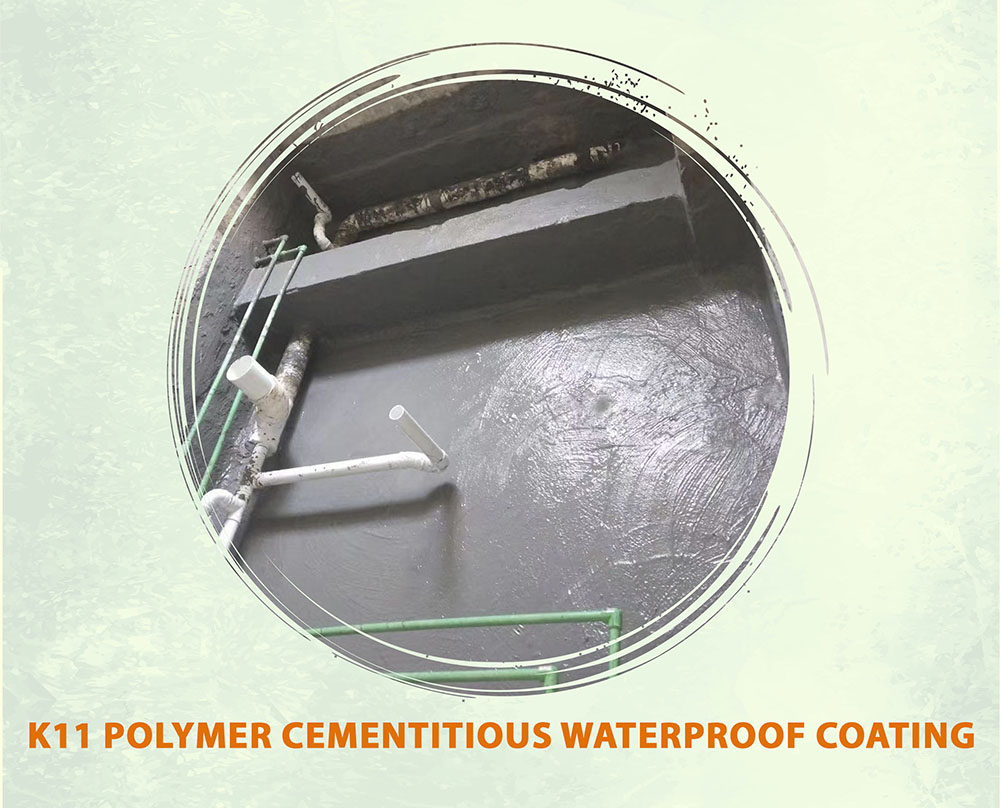

Kumanga Kwambiri K11 polima cementitious zokutira madzi

ZAMBIRI ZAMBIRI

- Zamalonda

- Kugwiritsa Ntchito Mankhwala

- Kukonzekera kwa Base

- Product Parameters

- Zomangamanga Technology

- Zindikirani

- Transport ndi Kusungirako

- Phukusi

*Ndemanga Zazinthu:

1. Ikhoza kumangidwa pachonyowa m'munsi pamwamba;

2. Kumamatira kwamphamvu ndi gawo lapansi, zosakaniza zogwira ntchito mu slurry zimatha kulowa mu capillary pores ndi zitsime zazing'ono zomwe zili m'munsi mwa simenti kuti zipange mankhwala. Zimaphatikizidwa ndi gawo lapansi kuti apange wosanjikiza wandiweyani wopanda madzi;

3. Pambuyo zouma ndi olimba, si koyenera kupanga matope wosanjikiza zoteteza mwachindunji muiike matailosi ndi njira zina;

4. Mphamvu yamadzi imakhalabe yosasinthika ikagwiritsidwa ntchito pamwamba pa mtsinje kapena pansi pa madzi;

5. Chigawo chachikulu cha mankhwalawa ndi zinthu zakuthupi, zomwe zilibe vuto la ukalamba ndipo zimakhala ndi madzi osatha;

6. Kutha kwa mpweya wabwino kuti gulu likhale louma;

7, yopanda poizoni, yopanda vuto, yopanga zachilengedwe.

* Kugwiritsa Ntchito Zinthu:

M'nyumba ndi panja mulch kapangidwe, pansi simenti, mankhwala osalowa madzi makoma amkati ndi akunja, khitchini ndi bafa.

Kuletsa madzi kwa nyumba zokhala ndi zokhazikikamonga nyumba zamafakitale, ntchito zosungira madzi, zosungiramo mbewu, ngalande, malo oimikapo magalimoto mobisa, makoma apansi, maiwe osambira, maiwe amadzi akumwa, ndi zina zambiri.

*Kukonzekera koyambira:

1. Gawo laling'ono liyenera kukhala lolimba, lathyathyathya, loyera, lopanda fumbi, mafuta, sera, zotulutsa, etc. ndi zinyalala zina;

2. Pores ang'onoang'ono ndi trachoma akhoza kusakaniza ndi ufa wa Kl 1 ndi madzi pang'ono kuti apange misa yonyowa, ndikuwongolera;

3. Musanapente slurry, nyowetsani gawo lapansi pasadakhale, koma pasakhale madzi osasunthika.

4. Gawo: Gawo A slurry: Gawo B ufa, 1: 2 (chiŵerengero cha kulemera) kapena 1: 1.5 malinga ndi zofunikira za phukusi.

*Zigawo Zazinthu:

| Ayi. | Zinthu Zoyesa | Zotsatira za Data | |

| 1 | Nthawi Yowuma | Pamwamba Wouma, h ≤ | 2 |

| Hard Dray, h ≤ | 6 | ||

| 2 | Osmotic kuthamanga kukana, Mpa ≥ | 0.8 | |

| 3 | Kusakwanira, 0.3Mpa, 30min | wosalowerera | |

| 4 | Kusinthasintha, N/mm, ≥ | Lateral deformation mphamvu, mm, | 2.0 |

| Kukhazikika | woyenerera | ||

| 5 | Mpa | Palibe mankhwala pamwamba | 1.1 |

| Pansi yonyowa | 1.5 | ||

| Alkali ankachitira pamwamba | 1.6 | ||

| Chithandizo cha kumizidwa | 1.0 | ||

| 6 | Compressive mphamvu, Mpa | 15 | |

| 7 | Flexural mphamvu, Mpa | 7 | |

| 8 | Kukana kwa alkali | Palibe kusweka, palibe kusenda | |

| 9 | Kukana kutentha | Palibe kusweka, palibe kusenda | |

| 10 | Kukana kuzizira | Palibe kusweka, palibe kusenda | |

| 11 | Kuchepa,% | 0.1 | |

*Tekinoloje ya zomangamanga:

Thirani ufa mu chidebe chodzaza ndi madzi, yambitsani makina kwa mphindi zitatu mpaka palibe mpweya wa colloid, kenaka muyime kwa mphindi 3-5, ndikuyambitsanso kuti mugwiritse ntchito. Kugwedeza kwapakatikati kuyenera kusungidwa pakagwiritsidwe ntchito kuti kupewe mvula. Gwiritsani ntchito burashi yolimba, chodzigudubuza kapena sprayer kuti mutsuka mofanana kapena kupopera slurry wosakanikirana pamtunda wonyowa; zomanga wosanjikiza, ndi burashi malangizo a wosanjikiza yachiwiri ayenera perpendicular kwa wosanjikiza woyamba; makulidwe aliwonse sayenera kupitirira 1mm.

*Zindikirani:

Kutentha kwa zomangamanga ndi 5 ℃-35 ℃; slurry pambuyo kusintha ayenera kugwiritsidwa ntchito mkati 1 ora; maziko apansi amayenera kutsukidwanso asanamangidwe simenti ya calendering base; Ndikofunikira kugwiritsa ntchito matailosi a ceramic pomangira matailosi pazitsulo zosanjikiza madzi.

*Mayendedwe ndi Kusungirako:

1. Pewani dzuwa ndi mvula, sungani pamalo owuma ndi mpweya wabwino.

2. Ponyamula, iyenera kuyimitsidwa kuti isapendekeke kapena kutsika, ndikuphimba ndi nsalu ngati kuli kofunikira.

3. Pansi pazikhalidwe zosungirako ndi zoyendetsa, nthawi yosungiramo ndi chaka chimodzi kuyambira tsiku lopangidwa.